Bosch ME7.1: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

The ECU appears to use two 16bit Infineon [http://nyet.org/cars/files/c167cr_ds_v3.3_2005_02.pdf B59233-FA (aka SAK-C167CR-4RM)] CPUs. Non-volatile code/data is stored on a single 16bit AM29F800BB 44 pin PSOP |

The ECU appears to use two 16bit Infineon [http://nyet.org/cars/files/c167cr_ds_v3.3_2005_02.pdf B59233-FA (aka SAK-C167CR-4RM)] CPUs. Non-volatile code/data is stored on a single 16bit AM29F800BB 44 pin PSOP |

||

ME7 is a [[load]] based engine management system. |

|||

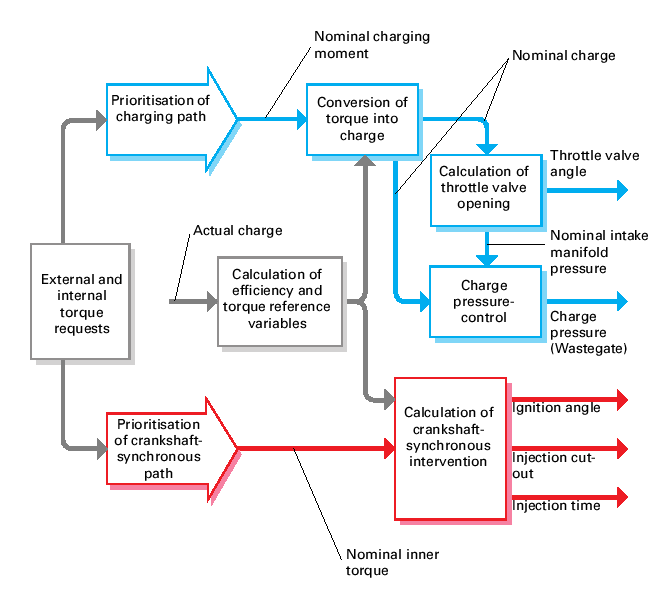

ME7 continuously calculates a "target torque" that the user seems to be requesting. This, in turn generates a "requested [[load]]", which is capped by "specified corrected [[load]]" (a function of RPM, IAT and other limiting parameters, such as knock control, etc.). This requested [[load]] determins the throttle plate angle and requested boost. |

|||

Once the ECU decides the requested [[load]] is large enough(?), its fueling control system goes [[open loop]]. In the [[ME7.1]] [[asynchronous path]], this means that all fueling decisions are going to be made almost soley based on [[Mass air flow|mass air flow sensor]] readings. Those [[mass air flow|MAF]] readings also go into the fueling maps as a "engine [[load]]" and are used to generate injector on times independent of O2 sensor readings. |

|||

In the ME7.1 [[synchronous path]], the timing maps determine the timing at every cycle of every cylinder, and should the knock sensor for a given cylinder reach a certain threshold, the timing will be cut down for the next cycle for that cylinder. If the knock sensor activity subsides, the timing will be restored, one step at a time, until another knock event occurs on that cylinder. |

|||

Block diagram of the torque ([[load]]) based system's control flow: |

Block diagram of the torque ([[load]]) based system's control flow: |

||

Revision as of 18:13, 21 January 2008

The ECU appears to use two 16bit Infineon B59233-FA (aka SAK-C167CR-4RM) CPUs. Non-volatile code/data is stored on a single 16bit AM29F800BB 44 pin PSOP

ME7 is a load based engine management system.

ME7 continuously calculates a "target torque" that the user seems to be requesting. This, in turn generates a "requested load", which is capped by "specified corrected load" (a function of RPM, IAT and other limiting parameters, such as knock control, etc.). This requested load determins the throttle plate angle and requested boost.

Once the ECU decides the requested load is large enough(?), its fueling control system goes open loop. In the ME7.1 asynchronous path, this means that all fueling decisions are going to be made almost soley based on mass air flow sensor readings. Those MAF readings also go into the fueling maps as a "engine load" and are used to generate injector on times independent of O2 sensor readings.

In the ME7.1 synchronous path, the timing maps determine the timing at every cycle of every cylinder, and should the knock sensor for a given cylinder reach a certain threshold, the timing will be cut down for the next cycle for that cylinder. If the knock sensor activity subsides, the timing will be restored, one step at a time, until another knock event occurs on that cylinder.

Block diagram of the torque (load) based system's control flow:

References

- Andy Whittaker's excellent site

- Me-motronic Engine Management from Amazon.com.uk (ISBN 3-934584-34-9)

- The 2.7-litre V6 Biturbo Design and Function Self-study Programme 198

- A New Approach to Functional and Software Structure for Engine Management Systems - BOSCH ME7

- B59233-FA (aka SAK-C167CR-4RM) Datasheet