Mass air flow: Difference between revisions

(discussion of reverse flow) |

|||

| Line 7: | Line 7: | ||

===Hot film MAF=== |

===Hot film MAF=== |

||

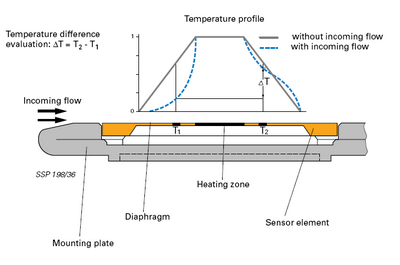

A hot film MAF is comprised of a diaphragm with a heating zone and two symmetrically arranged temperature sensors on either side of the heating zone. A control circuit maintains the heating zone at an overtemperature such that the downstream sensor reads a slightly lower temperature. The more air that blows past the upstream sensor, the cooler it is when compared to the downstream sensor. Thus, the difference in temperature between the upstream and downstream temperature sensor is proportional to the amount (and direction) of air mass flowing over the membrane. |

A hot film MAF is comprised of a diaphragm with a heating zone and two symmetrically arranged temperature sensors on either side of the heating zone. A control circuit maintains the heating zone at an overtemperature such that the downstream sensor reads a slightly lower temperature. The more air that blows past the upstream sensor, the cooler it is when compared to the downstream sensor. Thus, the difference in temperature between the upstream and downstream temperature sensor is proportional to the amount (and direction) of air mass flowing over the membrane. A thin film MAF can also detect a reverse flow of air, which may happen during high load factors. Reverse flow pulses from the pistion generate waves in the air upstream of the throttle body, and should not be allowed to affect the meter's readings. |

||

==S4 specific information== |

==S4 specific information== |

||

Revision as of 07:18, 1 August 2006

General information

A mass air flow (or MAF) sensor placed just before the intake manifold measures the instantaneous rate of air entering the combustion chamber. This is done using a thin wire or film suspended in the air stream.

Hot wire MAF

A hot wire MAF is composed of a thermistor wire and an ammeter. Since the MAF wire is a "positive k" thermistor, the hotter it gets, the higher its resistance. The colder it gets, the lower its resistance, and the more current that passes through the wire. However, the more current flowing through the wire, the hotter it gets (similar to an electric heater). This sets an upper stable limit of current, since as the resistance of the wire increases, the less current that flows through it. This "stable" point changes depending on how much air is flowing past the wire, providing cooling. The more air flowing past the wire, the more current the wire can allow through before it heats up enough to offset the current. Therefore, at any given time, the amount of air flowing through the MAF is proportional to the amount of current flowing through the wire in the sensor.

Hot film MAF

A hot film MAF is comprised of a diaphragm with a heating zone and two symmetrically arranged temperature sensors on either side of the heating zone. A control circuit maintains the heating zone at an overtemperature such that the downstream sensor reads a slightly lower temperature. The more air that blows past the upstream sensor, the cooler it is when compared to the downstream sensor. Thus, the difference in temperature between the upstream and downstream temperature sensor is proportional to the amount (and direction) of air mass flowing over the membrane. A thin film MAF can also detect a reverse flow of air, which may happen during high load factors. Reverse flow pulses from the pistion generate waves in the air upstream of the throttle body, and should not be allowed to affect the meter's readings.

S4 specific information

The B5 S4's Bosch Motronic ME7.1 ECU uses a mass air flow based fuel injection system. During open loop (engine warm-up and wide open throttle) operation, the MAF tells the ECU how much fuel to deliver to keep the air fuel ratio at an optimal level (also known as stoichiometric). Note that during closed loop operation (idle and partial throttle), the O2 sensors are used to determine fueling, not the MAF.

Temperature (IAT) effect on MAF

Because of their design, both the Bosch and Hitachi MAF correct for ambient temperature internally, so the ECU does not use the IAT sensor in its load calculations.

Bosch vs. Hitachi

B5 S4s came with two different types of MAF sensors - Hitachi and Bosch (part numbers?); both are film-type MAFs. Each has totally different characteristics and wiring. A-box cars (MY2000 to some of MY2001.0) came with Bosch MAFs. H-box (part way through MY2001 and later) cars came with Hitachi MAFs. To add to the confusion note that some MY2001.0 cars are A-box and some are H-box. M-box cars are generally considered MY2001.5.

| A-box/S8/RS4 aka Bosch |

H-box and M-box aka Hitachi | |||

|---|---|---|---|---|

| pin | color | wire | color | wire |

| 1 | blank/unused | none | violet/grey | +5V |

| 2 | green/yellow | +12V (ign/bat) | green/yellow | +12V (ign/bat) |

| 3 | black/green | ground | black/green | ground |

| 4 | violet/grey | +5V | green | signal |

| 5 | green | signal | blank/unused | none |

Trouble shooting/tuning

Logging

- max min values?

Bad MAF

- unplugging -> always closed loop (ECU uses O2 and MAP only)

- Audi 2.7t self study guide page 50 says "If the air mass meter fails, the air mass is calculated on the basis of a characteristic curve (throttle valve angle and engine speed)"

How MAF housing affects readings

- larger housing -> smaller value

- ECU has fixed top end reading, so have to scale MAF if we want more HP (since more HP means more air will be passing through MAF)

- more air means we need more fuel - larger injectors, higher pressure FPR

- how to scale MAF housing diameter with injector size and fuel pressure.

MAF and fueling

- how lemmi fueling (pri/second/accell/decel)

- affects open loop fueling (MAF vs injector duty)

- affects closed loop fueling (LTFTs)

- see also lemmi doc.

MAF and BOV vs BPVs

- metering escaped air can lead to rich conditions and incorrect LTFTs