Mass air flow

General information

A mass air flow (or MAF) sensor placed just before the intake manifold measures the instantaneous rate of air entering the combustion chamber. This is done using a thin wire or film suspended in the air stream.

Hot wire MAF

A hot wire MAF is composed of a thermistor wire and an ammeter. Since the MAF wire is a "positive k" thermistor, the hotter it gets, the higher its resistance. The colder it gets, the lower its resistance, and the more current that passes through the wire. However, the more current flowing through the wire, the hotter it gets (similar to an electric heater). This sets an upper stable limit of current, since as the resistance of the wire increases, the less current that flows through it. This "stable" point changes depending on how much air is flowing past the wire, providing cooling. The more air flowing past the wire, the more current the wire can allow through before it heats up enough to offset the current. Therefore, at any given time, the amount of air flowing through the MAF is proportional to the amount of current flowing through the wire in the sensor.

Hot film MAF

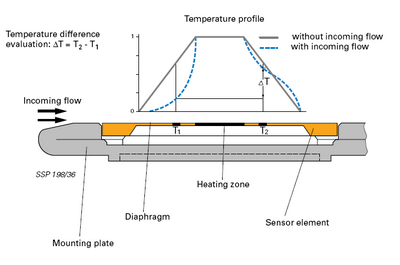

A hot film MAF is comprised of a diaphragm with a heating zone and two symmetrically arranged temperature sensors on either side of the heating zone. A control circuit maintains the heating zone at a constant overtemperature above ambient such that the downstream sensor reads a lower (but constant) temperature. The more air that blows past the upstream sensor, the cooler it is when compared to the downstream sensor. Thus, the difference in temperature (ΔT) between the upstream and downstream temperature sensor is proportional to the amount (and direction) of air mass flowing over the membrane. A thin film MAF can also detect a reverse flow of air, which may happen during high load factors. Reverse flow pulses from the pistion generate waves in the air upstream of the throttle body, and should not be allowed to affect the meter's readings.

S4 specific information

The B5 S4's Bosch Motronic ME7.1 ECU uses a mass air flow based fuel injection system. During open loop (engine warm-up and wide open throttle) operation, the MAF tells the ECU how much fuel to deliver to keep the air fuel ratio at the desired level. Generally, open loop fuel ratios are not stoichiometric, so narrow band O2 sensors can not be used for this. Thus, for proper functioning, MAF readings are critical for proper open loop behavior; there is no way for ME7.1 to detect if the fueling is off.

Unlike wideband O2 sensor equipped cars, the ME7.1's narrow band O2 readings are ignored during open loop operation. The O2 sensors (along with MAF readings) are used to determine fueling only during closed loop operation (idle and partial throttle). Note that since MAF readings are also used during closed loop operation, long term fuel trims (or LTFTs) may be affected by faulty or incorrectly tuned MAF setups, including the use of blow off valves (or BOVs).

Temperature (IAT) effect on MAF readings

Because of their design, both the Bosch and Hitachi MAF correct for ambient temperature, so the ECU does not use the IAT sensor in its load calculations.

Both types of thin film MAF keep the heating element at a constant overtemperature above ambient, so the ΔT between the upstream and the downstream sensor will always give a "cooling capacity" of the mass of air passing over the film. By holding the overtemperature constant, the "cooling capacity" is linear with the air mass passing over the film, regardless of IAT.

IAT effect on timing and fueling

However, IAT does play a role in adjusting the base timing and fueling maps. Unfortunately, those adjustments are done before any correction factor (ignition retard) that comes from the knock control function, so IAT related timing adjustment values are not visible to tools like VAGCOM or ECUx. In general, the higher the IAT is above approximately 50°C (~120°F), the more timing will be pulled and the more fuel will be added.

Bosch vs. Hitachi

B5 S4s came with two different types of MAF sensors - Bosch (078 906 461B) and Hitachi (06C 133 471A); both are film-type MAFs. Each has totally different signal characteristics and are not compatible, even if properly rewired. A-Box/B-Box cars (MY2000) came with Bosch MAFs. H-Box/J-Box (MY2001), M-Box/L-Box (MY2001.5), and T-Box/AA-Box (MY2002) cars came with Hitachi MAFs.

| A-Box/B-Box/S8/RS4 aka Bosch |

H/J/M/L/T/AA-Box aka Hitachi | |||

|---|---|---|---|---|

| pin | color | wire | color | wire |

| 1 | blank/unused | none | violet/grey | +5V |

| 2 | green/yellow | +12V (ign/bat) | green/yellow | +12V (ign/bat) |

| 3 | black/green | ground | black/green | ground |

| 4 | violet/grey | +5V | green | signal |

| 5 | green | signal | blank/unused | none |

Changing from one "box" to another is as easy as unplugging one ECU and plugging in another. Some tuners offer "flash" upgrades where an ECU can be reprogrammed via the OBD-II port. However, changing ECU boxes may also require a cluster recode and a MAF conversion.

List of needed parts to convert a Bosch MAF to a Hitachi MAF:

| Part number | Qty | Description |

|---|---|---|

| 06C 133 471A | 1 | Hitachi MAF with housing (add “X” to part number for remanufactured) |

| 1J0 973 705 | 1 | Housing (aka plug) |

| 4A0 906 102 | 1 | Grommet (aka boot) |

| 000 979 131A | 3 | Wires with connectors |

| 357 972 741 | 5 | Weather seals for wires into the housing |

| 111 971 940A | 5 | Weather sealed butt connectors as used by VW/Audi as the OEM way to repair a wiring break. |

AWE has excellent instructions on how this is done.

Logging/tuning/trouble shooting

Signal conditioning

- For the Hitachi MAF

- 0-0.5V means negative air flow?

- 0.5V is zero air flow?

- 5.0V is maximum reading.

- the ECU reads roughly g/sec. Although the voltage to grams/sec conversion is independant of IAT, it appears as though the ECU has a correction factor that goes up with RPM.

- can "tweak" measured maf values by using a piggyback signal conditioner

- Bosch is similar, but convex shaped transfer function?

MAF housing diameter

- MAF signal has an absolute top end reading of 5 volts. So have to scale MAF if we want more HP (since more HP means more air will be passing through MAF).

- To keep the signal under 5 volts for the maximum air flow, we have to make the diameter larger. This will make the signal smaller for a given air mass flow.

- For a given mass air flow:

- air velocity goes down with cross sectional area

- cooling capacity goes down with cross sectional area or diameter?

- voltage goes down with diameter?

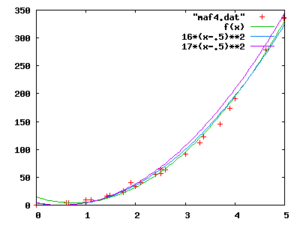

- MAF reading therefore down with square of diameter and with crossectional area

- more air means we need more fuel - larger fuel injectors, higher pressure FPR

- how to determine MAF housing diameter vs injector size and fuel pressure (fuel flow).

Effect on Airflow

One way to determine how big a housing to use for a MAF value is by simply comparing cross sectional areas using percentages.

Cross sectional area is given by

where D is the MAF housing diameter in mm. (e.g. 88mm, 90mm, etc.)

Since the stock cross sectional area is (73 being the stock MAF housing size in mm), the increase in MAF (g/s) in %

| MAF | Diameter | Deviation | Measured airmass | True airmass |

|---|---|---|---|---|

| AWE | 85mm* | +35.6% | 364 g/sec | 493 g/sec |

| ASP | 85mm | +35.6% | 493 g/sec | |

| Custom | 88mm | +45.3% | 528 g/sec | |

| ASP | 90mm | +52.0% | 553 g/sec |

- AWE actual dimensions are 77mm (inlet) to 100mm at sensor. It reads roughly equivalent to an 84mm-86mm MAF, but the response isn't exactly equivalent at all airflow magnitudes.

Effect on Velocity

Velocity is a good way to approximate the maximum airflow that can be measured by a sensor, because it is independent of the housing's cross sectional area.

A strong S4 running stock K03s, MAF, and fueling uses approximately 260 g/sec of air.

To calculate velocity, we convert the g/sec into (volume of air per second) by dividing by 1225 (density of air at sea level).

We then divide by the cross sectional area of the housing ().

| MAF | Diameter | Max airflow | Velocity | |

|---|---|---|---|---|

| Stock | S4 | 73mm | 220 g/sec | 96 mph |

| Stock | RS4 | 83mm | 320 g/sec | 108 mph |

| Chipped | S4 | 73mm | 260 g/sec | 113 mph |

| Stage 2+ | S4 | 73mm | 280 g/sec | 122 mph |

| VAGCOM limit | RS4 | 83mm | 364.08 g/sec | 122 mph |

| Stage 3- | S4 | 73mm | 310 g/sec | 135 mph |

| 5V at sensor | S4 | 73mm | 364? g/sec | 159 mph |

| 5V at sensor | RS4 | 83mm | 499 g/sec | 168 mph |

- VAGCOM limit seems to be 318ish on M/T-box, 335ish for M-box, high 320s for A box.

- Sensor value absolute maximums are 364.08 on VAGCOM and 499 on ECUx.

- Note that some programs scale g/sec readings, so what ECUx/VAG-COM reports can't always be trusted.

Using the maximum velocity

As you can see, the maximum velocity measured by both the Hitachi and Bosch sensors is approximately 160mph. We can use this value to determine what size housing we need to measure a given maximum amount of air mass with a given sensor.

| MAF | Diameter | Velocity | Measured airmass | True airmass |

|---|---|---|---|---|

| AWE | 85mm* | 160mph | 367 g/sec | 497 g/sec |

| ASP | 85mm | 497 g/sec | ||

| Custom | 88mm | 533 g/sec | ||

| ASP | 90mm | 558 g/sec |

- AWE actual dimensions are 77mm (inlet) to 100mm at sensor. It reads roughly equivalent to an 84mm-86mm MAF, but the response isn't exactly equivalent at all velocities.

MAF and fueling

- how lemmi fueling (pri/second/accell/decel)

- affects open loop fueling (MAF vs injector duty)

- affects closed loop fueling (LTFTs)

- see also Lemmiwinks.

Bad MAF

- Unplugging the MAF will result in the ECU thinking it is broken. Some think this will prevent the ECU from ever going open loop, some think that the ECU can go open loop, but the MAF signal is simply ignored.

- The Audi 2.7t self study guide (page 50) says "If the air mass meter fails, the air mass is calculated on the basis of a characteristic curve (throttle valve angle and engine speed)"

- Is the MAP used in "characteristic curve" calculations?

- If so, what does the ECU do in the case where it thinks the MAP is dead?